Transport of dangerous goods

Transport of dangerous goods in Serbia is regulated by the Law on transport of dangerous goods, agreements on international dangerous goods transport: ADR, RID and ADN, as well as series of subordinate regulations.

CIAH Laboratory is appointed and certified inspection body in Serbia in accordance to aforementioned regulations by The Ministry of Construction, Traffic and Infrastructure to carry out the testing and inspection of vehicles, tanks, battery vehicles, MEGC and packaging used for the transport of dangerous goods.

CIAH Laboratory organizes, in accordance to the license of The Ministry of Construction, Traffic and Infrastructure, a professional training of candidates for an advisor for transport of dangerous goods, as well as other trainings in this field, upon request.

The inspection of vehicles for dangerous goods transport

In accordance to ADR Agreement, every vehicle of categories N and O, types FL, AT, EX/II, EX//III and MEMU, has to meet the requirements of said Agreement.

Every complete or completed vehicle has to go through an initial inspection, as well as an inspection of technical characteristics once a year in a country it has been registered in.

The conformity of a vehicle has to be endorsed via a certificate of vehicle approval, which is issued in Serbia by an appointed inspection body (ADR Certificate).

Approval certificate is valid for a year from the day of the inspection of technical characteristics that preceded its issuance.

Accredited inspection body, CIAH Laboratory, is appointed by The Ministry of Construction, Traffic and Infrastructure to assess the dangerous goods transport vehicle compliance, that is for the inspection for issuance of ADR Certificate.

For the inspection, the following documentation is to be provided:

- application (by the owner or user of the vehicle)

- vehicle registration document

- precedent ADR Certificate

- manufacturer’s confirmation that the vehicle meets the requirements of ADR Agreement for a specific type (FL, AT, EX/II, EX/III and MEMU – if the new vehicle or the vehicle being registered in Serbia for the first time is in question

- report (certificate) on last committed tank inspection (for tank vehicle) and additional documentation for the tank upon the CIAH Laboratory’s request

- certificate for tachograph testing (for N2 or N3 vehicle).

Nenad Jovanović, +381 (0) 62 295 839;

еmail: njovanovic@mas.bg.ac.rs

Ivan Ivanković, +381 (0) 62 295 729;

еmail: iivankovic@mas.bg.ac.rs

Type approval

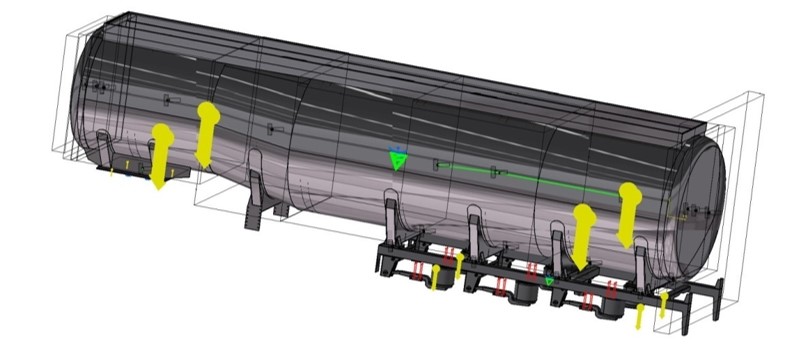

According to the ADR/RID Agreements, battery vehicles and MEGC are subjected to the following inspections – conformity assessments:

- type approval inspection (for new type)

- initial inspection, before the release into exploitation.

- conformity of a tank used for dangerous goods transport in road transport

- conformity of a tank used for dangerous goods transport in rail transport

- conformity of mobile equipment under pressure used for dangerous goods transport.

Nenad Jovanović, +381 (0) 62 295 839;

еmail: njovanovic@mas.bg.ac.rs

Vlastimir Joksimović, +381 (0) 62 295 268;

email: vjoksimovic@mas.bg.ac.rs

Ivan Ivanković, +381 (0) 62 295 729;

еmail: iivankovic@mas.bg.ac.rs

Tank type approval and initial inspection

For every new construction type of a tank, an inspection and testing for type approval is carried out, after which the certificate that the tested type, including the equipment, is approved to be used as intended and that it corresponds to the manufacturing requirements, equipment requirements and special conditions of substance transported in it is issued.

The manufacturer or their certified representative have to provide the documentation containing following information in order for a type approval inspection to take place:

- name and address of the application submitter

- tank prototype description including planned variations in construction and its special characteristics

- names and addresses of manufacturers and assembly plants; in case of tank vehicles or rail tanks: chassis or carriage project; in case of container-tanks or portable tanks: manufacturer’s name and frame project if applicable

- certificates for welders, welding technology and quality system in welding in accordance with technical regulations

- anticipated working mode description (e.g. outlet pressure)

- remark on instruction T and special provisions TP for portable tanks or tank code and valid special provisions TA (type approval), TC (construction) and TE (equipment)

- if required, list of all substances or groups of substances the tank is intended to transport (especially class 2 substances and special substances that might need special requirements)

- scheme of a tank with main dimensions

- schemes of plumbing systems

- data list of operating data for a tank needed for calculations

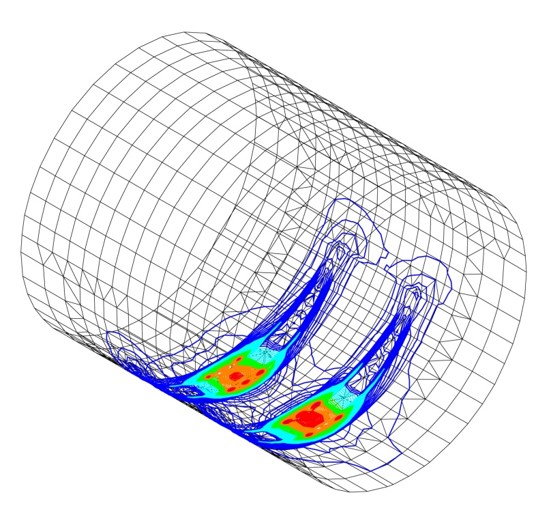

- tank and joint calculations according to a valid dangerous goods transport regulations and, if required, calculation verification by testing tank and joints

- equipment and joints drawings needed for manufacturing verification, including assembly drawing and bill of material

- marking drawings (identification plate and similar)

- list of service equipment with relevant technical data including compliance certificates

- suitability of safety device including bleed valve capacity calculation if required

- specification of materials used in tank manufacturing, that includes material characteristics data required by the regulation and implies technical code (including welding material and safety coating)

- certificates on material testing in accordance with implied technical code for all materials used in tank manufacturing, that include material characteristics data required by the regulation, for tank prototype, including welding material and safety coating

- test report on testing in manufacturing process trial, if required by the technical code and/or appropriate regulations concerning dangerous goods transport (recordings and their connection with trials has to be checked by a professional)

- when safety coating is used, requirements of safety coating manufacturer concerning testing that the coating has been used in accordance with the manufacturer’s specification

- needed requirements for determination of delay time, for tanks used for the transport of deeply cooled liquefied gases, if applicable

- test report for non-destructive testing of welded joints

- certificates of qualification for employees responsible for non-destructive testing in accordance with technical code

- if required, approval of used non-destructive testing method

- thermal processing process and reports (if used).

- application form

- type approval certificate

- if needed, data given in type approval application form

- certificates for welders, welding technology (technology qualification) and quality system in welding in accordance with technical regulations

- specification of materials used for tank manufacturing, that includes material characteristics data required by the regulation and implies technical code (including welding material and safety coating)

- test report on testing in manufacturing process trial, if required by the technical code and/or appropriate regulations concerning dangerous goods transport (recordings and their connection with trials has to be checked by a professional)

- when safety coating is used, proof that the coating is compatible with the substance to be transported in a tank

- when safety coating is used, proof that the coating is tested and used in accordance with the manufacturer’s specification

- needed requirements for determination of delay time, for tanks used for the transport of deeply cooled liquefied gases, if applicable

- test report for non-destructive testing of welded joints

- certificates of qualification for employees responsible for non-destructive testing in accordance with technical code

- thermal processing process and reports

- volume calculation, if required.

Type approval for battery vehicle and MEGC

For every new type of construction of a battery vehicle or MEGC, inspection and testing takes place for the type approval, after which the certificate is issued confirming that the tested type, including its equipment, is appropriate to be used and complies with manufacturing requirements, equipment requirements and special conditions for substances to be transported.

Documentation to be provided for the type approval is defined by the inspection body depending on the battery vehicle/MEGC and requirements of the standard.

Inspection of a tank during exploitation

According to ADR/RID Agreement, tank bodies and parts of their equipment undergo the following inspections during exploitation:

- periodic inspection

- intermediate inspection

- exceptional check after a reparation (in case of a reparation), possibility of a reparation due to the traffic accident, refit or any change on the tank.

For periodic inspection, the following documentation or its photocopies are to be provided:

- first inspection certificate, if the tank was not subjected to periodic inspection,

- last periodic inspection certificate, if applicable,

- intermediate inspection certificate, if carried out after the last periodic inspection or after first inspection if there was no periodic inspection,

- list of technical data for type approval, applicable for tanks whose first inspection was carried out according to named version of the standard,

- necessary applications for delay time, for tanks used for the transport of deeply cooled liquefied gases, if applicable,

- other documentation, if necessary, upon request.

- first inspection certificate, if the tank was not subjected to periodic inspection,

- last periodic inspection certificate, if applicable,

- list of technical data for type approval, applicable for tanks whose first inspection was carried out according to named version of the standard,

- other documentation, if necessary, upon request.

Contact:

Nenad Jovanović, +381 (0) 62 295 839;

еmail: njovanovic@mas.bg.ac.rs

Ivan Ivanković, +381 (0) 62 295 729;

еmail: iivankovic@mas.bg.ac.rs

Packaging

For each new packaging type, construction type testing is carried out. Also, for the IBC, inspections during exploitation in regular time intervals are carried out.

Accredited inspection body, CIAH Laboratory, is appointed by The Ministry of Construction, Traffic and Infrastructure for determination of compliance of packaging.

Apart from the application and samples for testing the construction type, the following is to be provided:

- technical documentation (drawings, mass data, marking codes etc.),

- certificates for the materials the packaging is manufactured from,

- documented process of packaging manufacturing (spraying, die-casting etc.).

Contact:

Professor Branislav Rakićević, PhD, tel. +381 (0) 63 8252 191;

email: brakicevic@mas.bg.ac.rs

Vlastimir Joksimović, tel. +381 (0) 62 295 268; (for periodic control of IBC)

email: vjoksimovic@mas.bg.ac.rs

Safety advisor

In accordance with The law on transport of dangerous goods, as well as endorsed agreements on transport of dangerous goods (ADR/RID/ADN), every company in dangerous goods transport sector (including delivery, packaging, loading, unloading) has to have one or more dangerous goods transport safety advisors (except the cases stated in ADR/RID/ADN or The law on transport of dangerous goods).

Safety advisor, whose assignments are defined in aforementioned regulations, has to have a valid certificate for appropriate transport type. In Serbia, the certificate is issued by The Ministry of Construction, Traffic and Infrastructure. In order to gain a certificate, a candidate is to finish the training and pass the exam organized by mentioned Ministry.

Professional training of a candidate for safety advisor in Serbia is carried out by the organization licensed by The Ministry of Construction, Traffic and Infrastructure.

CIAH Laboratory, according to the license issued by The Ministry of Construction, Traffic and Infrastructure, conducts professional training of candidates for the safety advisors in dangerous goods transport in road (ADR) and railway (RID) transport, 45-60 days before the day of the exam.

Exam dates can be accessed at https://www.mgsi.gov.rs/lat/dokumenti/transport-opasne-robe-savetnik-za-bezbednost.

The training takes place on the Faculty of Mechanical Engineering in specialized classrooms. The training lasts for three days + 1 consultation day before the exam.

Contact:

Vlastimir Joksimović, tel. +381 (0) 62 295 268;

email: vjoksimovic@mas.bg.ac.rs